new 448 backhoe sags

| SamSpade

Join Date: May 2008 Posts: 41 Vermont

|

2008-08-05 155841

I got my new tractor with a 448 backhoe. But I am surprised how fast the boom hydraulics sag and trying to figure out if it is a problem or normal for the seals to bypass this much.

If I put the boom and dipper out at a 45%, I think the bucket would be on the ground in less than an hour.

I think there is a prescribed time limit that JD says is OK, does anyone know it and the standard position to start from? I am probably not facing a problem, but I would like to confirm it.

SS

Reply to |

new 448 backhoe sags

| auerbach

Join Date: Sep 2007 Posts: 2168 West of Toronto

|

2008-08-06 155842

Normal occurence -- when the unit is 25 years old. I'd expect new internal seals to hold for a half-day or so. ....

Reply to |

new 448 backhoe sags

| harvey

Join Date: Sep 2000 Posts: 1550 Moravia, NY

|

2008-08-06 155844

There are several threads about this and the general consensus is (weather right or wrong) they bleed down fairly quick.

My 48 does also from day 1. I think it is more of a function of the valves in the valve block. ....

Reply to |

new 448 backhoe sags

| kthompson

Join Date: Oct 2005 Posts: 5278 South Carolina

|

2008-08-06 155853

Based upon Harvey's comment doubt the JD boom has valves that are designed to hold the boom up with the machine off for safety. Look in your manual and see if they say anything about them "holding" if pressure is lost. Some do for safety. You can cut off the machine and break the pressure and the boom will hold. kt ....

Reply to |

new 448 backhoe sags

| SamSpade

Join Date: May 2008 Posts: 41 Vermont

|

2008-08-06 155862

I didn't see anything about a safety when there is no machine pressure on my first read through the manual. I'll go back and check to see if I missed it.

Earlier I was speaking about with the machine on, but I do know it will settle with the machine off also. I'll try it with the machine off and then on to see if there is a difference.

I tried searching past threads on hydraulic issues, but I didn't come up with anything related to settling like this. Does anybody know the site well enough to suggest a search criteria that might get me closer?

SS ....

Reply to |

new 448 backhoe sags

| earthwrks

Join Date: Dec 2003 Posts: 3853 Home Office in Flat Rock, Michigan

|

2008-08-06 155875

I'm wondering why you'd leave the boom in any position but fully up or fully down. And that it stops in any position is not so much for "safety" but that's its inherent design (Kenny, that means that is how it's designed to be). After all, if you release a control lever while you're digging in any position, you want that particular piece to stop while you're doing another function.

Hydraulics are not to be equated with a transmission in that if you're not going forward or reverse then you're in neutral and can go either way under its own volition--not so. In fact just the opposite. Generally, hydraulics are in a sort of hydraulic limbo until controlled otherwise.

It's sort of like saying a runner standing motionless must be in a "safety position". No, because just a second before that he was running. It's part of the running process---he's gotta start and stop sometime. ....

Reply to |

new 448 backhoe sags

| hardwood

Join Date: Dec 2002 Posts: 3583 iowa

|

2008-08-06 155879

The stabilizer cylinders will sag on my #48, but can't tell you about the boom, I always either put the safety pin in for transport or rest the bucket on the ground when if park it. Some cylinders on any equipment seem to leak back a bit or else the control valves leak a bit, unless they get real bad it isn't much of a concern. Frank. ....

Reply to |

new 448 backhoe sags

| SamSpade

Join Date: May 2008 Posts: 41 Vermont

|

2008-08-06 155889

EW, that's the point. I didn't buy it that it is a safety "feature", I want it to stay stopped when I tell it to stop, but it doesn't. And it is not that it sags over a couple of days, but while I watch. I'd stick it out at a 45 not to do anything but to put it into a high stress position in order to make the issue easier to see (faster). And it was more of a hypothetical. From my normal use and seeing how it reacts I am predicting how it will react if in that hypothetical position. I am trying to decide if is normal for it to sag this fast or if it means the cyclinder is leaking unacceptably.

When I spoke to my dealer about, he said that there might be a spec for how long it takes for it to sag from a specified position that indicates a problem or normal. But he didn't know the specs off the top of his head.

I don't have a lot of experience with this, so I am casting about in the wilderness looking for a ray of hope.... ;) ....

Reply to |

new 448 backhoe sags

| DRankin

Join Date: Jan 2000 Posts: 5116 Northern Nevada

|

2008-08-07 155892

I love my Deere but they all "sag" like that.

I have a 46 hoe and it drifts down like yours, as do the stabilizers and the FEL and sometimes the 3 point hitch.

If you do get the specs from Deere don't be surprised if they say that falling in just minutes is within spec.

There are actually three problems going on here.

1) The whole hydraulic system is spec'd pretty loose.

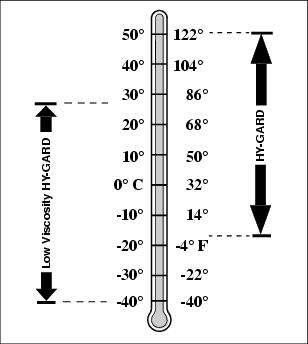

2) Deere (and dealers) keep filling tractors with Low-Vis Hygard with has the viscosity of warm water in spite of the fact that the owners manual calls for regular Hygard at temps over 80 degrees.

3) It is summer. See above.

When I replaced the low-vis in my system the problem didn't go away but it slowed WAY down. On a cold winter day the hydraulics will stay in place all day (12-18 hours).

Summer temps around here are 100 or so and I still get some drift-down in this weather..... about like it used to do in the winter on low-vis.

You may have to change oil twice or three times to get mostly regular Hygard through-out the system considering how much is left behind in hydraulic cylinders, hoses, other implements and such.

But I believe based on my observations and experience that it is the only realistic help you are going to get.

Check the folwing links:

http://eservice.msds.com/servlet/SSMain

http://www.deere.com/en_US/parts/partsinfo/oils_and_lubricants/oil_hydraulic.html

....

Link: Viscosity chart

Picture Link

Reply to |

new 448 backhoe sags

| hardwood

Join Date: Dec 2002 Posts: 3583 iowa

|

2008-08-07 155896

DRankin; Like you said changing from Lo-vis to Hi-vis can take several changes to get it completely changed. I do agree with you that the Lo-Vis has the consistency of rainwater, but the service manager tells me DON'T do it meaning leave the Lo-Vis in it year round. Kinda like the newer cars and pickups calling for the 0 - whatever viscosity engine oils year round, but nothing unusual to hear of cars running on the rainwater stuff to have a quarter million miles. One son in law has one with a tick over three hundred thousand and still going, kinda hard for me to believe too. Frank. ....

Reply to |

new 448 backhoe sags

| earthwrks

Join Date: Dec 2003 Posts: 3853 Home Office in Flat Rock, Michigan

|

2008-08-07 155897

Sam, I doubt very much that the cylinders are leaking internally. BUT to verify that, you could simply raise and block the boom, remove both lines from the offending cylinder (they will be under pressure until it lays on the blocking), then cap off the lines. Remove the blocking and see what happens. No drift? Then it's likely at the load check valves which are usually located in the control valve. Typically they are a cartridge-type meaning they simply screw in. From the top they look like a big bolt head. Adjustable ones have a lock nut and adjustable threaded rod/screw through the center.

Inside the load check is a spring-loaded ball that seats against a hollow cone. If the ball or the cone are defective, rusty, pitted, worn, or out-of-round---you'll lose the ability to effectively stop fluid and the resultant drift. ....

Reply to |

new 448 backhoe sags

| kthompson

Join Date: Oct 2005 Posts: 5278 South Carolina

|

2008-08-07 155906

I worked for a large manufacturer of hyd cranes and tested hundreds over the years. Any cylinder on those machines that supported a load had valves to hold the hyd pressure (we called them holding valves but EW calls them load check valves). They would hold a load if pressure were lost regardless the position the cyl was in. If a hose or hyd valve failed the cyl did not drift. NOW if the cyl failed that was a different issue and not a good one.

On the Volvo excavator I have it has the same type valves again on any cyl supporting the load but not on cyls that do not.

All being said have no idea if they are used on such as small FEL or backhoes or even all larger machines. It could be a requirement on machines with certain lift ability or those who know law suits and work to avoid them. No idea. kt

....

Reply to |

new 448 backhoe sags

| DRankin

Join Date: Jan 2000 Posts: 5116 Northern Nevada

|

2008-08-07 155908

Frank..... I hear ya loud and clear. They said the same to me.

But when I asked how it could be wrong to use the specified oil, labeled by Deere, they had no answers.

The chart in my last post is copied straight out of my owners manual.

Another interesting tidbit..... I cannot find a web page on the Deere site that extols the benefits of Low-Vis.

The only oil 'Corporate Deere' promotes on the web for ALL their tractors is Hy-Gard.

Also note that regular Hy-Gard has a pour point of -40 F and protects the transmission up to +122 F. That covers me with room to spare on both ends.

Every chart I have seen for Low-Vis indicates it has an even lower pour point and it runs out of spec at about 85 degrees F.

Perfect for coastal Alaska, not so good here.

....

Reply to |

new 448 backhoe sags

| earthwrks

Join Date: Dec 2003 Posts: 3853 Home Office in Flat Rock, Michigan

|

2008-08-07 155912

Kenny--load check valve is not my terminology--I got it from a hydraulic supplier catalog. I can't think of any application on a loader that would not have a load check valve. I'm told that a hydraulic circuit that doesn't have load check-- that should have one-- makes it nearly impossible to move the control levers. Having a load check valve allows the pressure inside the control valve to decrease while the check valve holds the built up pressure on the other side of the control valve spool. ....

Reply to |

new 448 backhoe sags

| earthwrks

Join Date: Dec 2003 Posts: 3853 Home Office in Flat Rock, Michigan

|

2008-08-07 155913

Kenny the holding valves you mentioned on cranes ARE for safety. My manlift has them for the boom and the basket. In fact just other day a hose blew for lifting the boom when I was on it and it kept ifrom flaiing.

Typically the safety valves they are mounted on the cylinder itself and usually have no flexible hoses that could lose pressure due to failure. ....

Reply to |

new 448 backhoe sags

| harvey

Join Date: Sep 2000 Posts: 1550 Moravia, NY

|

2008-08-07 155914

I really do not think you will see this type of valving on these small implements. They would add several hundred dollars to the cost. These are simple open close valves to keep cost reasonable.

Yes the big cats and other loaders, BH's, excavators have much higher quality valves and do not noticeabley leak down when new. BUT after several hundred hours of use they all leak down and the valve will cost in excess of thousand dollars to replace.

You wanna see expensive take a man lift that is 5 years old in for repair at a dealer. All systems are checked and ANYTHING out of tolerance is repaired or you do not get the machine back until it is. ....

Reply to |

new 448 backhoe sags

| SamSpade

Join Date: May 2008 Posts: 41 Vermont

|

2008-08-07 155916

I'll take a look and see if I can see check valves. Good point about the low vs high viscosity oil. I asked the dealer to send some makeup hydraulic oil and lube to match what they put in it for setup, so I can check if it was low or high viscosity.

SS ....

Reply to |

new 448 backhoe sags

| harvey

Join Date: Sep 2000 Posts: 1550 Moravia, NY

|

2008-08-08 155922

Sam there are not any check valves on the BH. Ive have the valve blocks apart. They are simple reliable open close 2 of the valves have reliefs built in one on boom and one on dipper.

You have good info on low vs hy oil. Personally I use the low the sagging is no problem. I do not suspend loads from hoe. The biggest pita is stabilizer legs settling when I spend 20-30 minutes working on my burn pit for garbage. ....

Reply to |

new 448 backhoe sags

| hardwood

Join Date: Dec 2002 Posts: 3583 iowa

|

2008-08-08 155924

DRankin; I read the same chart in the owners manual for the 4310. Our oldest son works for a major oil company doing senminars for engeneers and upper level maintinece people from various heavy industrys, so I posed the question to him about the super thin engine and transmission fluids of today. His response was that with the super close tolerences of the bearings in todays engines and transmissions you need the thin products to so to speak get between the bearing surfaces. Another comment he made was that if you choose to use to use for example a 10/30 engine oil instead of a 0/15 that the owners manual may call for the first engine componet to fail will be the oil pump, the thicker oil is just too much for it to push. After listening to him perhaps the reason the Deere service people ask us to use the Lo-Vis is that perhaps the transmissions and hydraulic componets have the tolerences that the Hi-Vis just won't fit between. Having car and pickup engines that will last 2 or 3 hundred thousand miles with just normal regular oil changes etc. is really great, now it they can figure out how to keep the body from falling off with a good engine still running fine we would really have something. Frank. ....

Reply to |

new 448 backhoe sags

| kthompson

Join Date: Oct 2005 Posts: 5278 South Carolina

|

2008-08-08 155926

EW, sorry I misunderstood what you were saying. It has only be 26 or so years since I played in those terms daily. You probably were still on milk then. :)

As to the comments on the cost of the holding valves, do not doubt you. One reason I was surprised my little excavator has them but glad it does.

On the orginal question, there is a commerical JD dealership I pass by often. They leave excavator booms just off the ground and they will hold at least for a weekend. It is good visual as traffic passes. If they do that on the TLB I am not sure. It would not surpise me that they would know any specs on this question better if the specs were to hold between the two product lines.

It would seem for the outriggers to leak down in 20 to 30 minutes would be a pain on some jobs. kt ....

Reply to |

new 448 backhoe sags

| earthwrks

Join Date: Dec 2003 Posts: 3853 Home Office in Flat Rock, Michigan

|

2008-08-08 155928

Harvey, I'm pretty sure (but been wrong before) those reliefs are actually load checks. Otherwise, like I stated earlier, you couldn't move the spool back and forth inside the control.

I have a power top link I made with complicated hydraulic cicuitry that comes from one source--the rear remote. I have two 4-way selector valves side by side (that control 2 circuits each). If there is pressure behind circuit, and before I realized what was happening, I had to literally pound on the exposed end of the selector valve spool to change direction.

Your relief valves are likely somewhere else up-line near the pump in a nondescript block having lines to and from it. On my medium size backhoe, the reliefs were about a foot away from the pump. ....

Reply to |

new 448 backhoe sags

| SamSpade

Join Date: May 2008 Posts: 41 Vermont

|

2008-08-08 155939

This reminds me of maintenance on my BMW motorcycle. I spent way too much money on a a very nice bike a couple of years ago. Since I paid so much money for it, and two wheels are different than four, redundancy wise, I generally let a dealership do the maintnance on it. A while ago, I took it in for a regular service interval and the tires needed replacing. I spent more on those two tires that go about 5-6 K miles than I do on the 4 ten ply tires that go on my one ton truck and go 40K + miles.

When I got the bike back, it would smoke at start up if it had been on the kickstand any length of time. It was not doing this when I brought it in. I questioned the dealer, didn't like the BS answer he gave me, went back for more. His final word was that BMW lists that consumption of less than 1 quart of oil per 300 miles was within spec. He didn't see a problem. I came to the conclusion that they had over filled the oil and it was laying agains the cylinder while on the kickstand and weeping past (this is one of those twin opposed engines). I drained some oil out, putting it in the dot on the sight glass and it went away. I also come away from that thinking that what's "ok" in the manual may not be the same as what's "OK" in the mind of the operator.

I'd like to figure out what JD calls out for a spec on the boom sagging. Mines probably OK. But since I don't have a lot of experience with hydraulics, and I am a coward, able to envision my own death (and by extension, the death of my equipement) a thousand times, I wouldn't mind getting the input of someone with more experience. Preferably someone who doesn't have a dollar sign at the begining of thier motivation....

Thanks for the insight offered. ....

Reply to |

new 448 backhoe sags

| harvey

Join Date: Sep 2000 Posts: 1550 Moravia, NY

|

2008-08-09 155955

I not try to complicate this. The valve body consists of 8 (if I remember Correctly) valve bodies. They are simple open close valves there are no fancy pressure check valves etc. If boom in air and hose rupture it is coming down, if boom in air and you loosen fitting it coming down. The dipper and boom have a relief valve on the rod extend side of valve to prevent a hard stop rod bottom out in cylinder. If one of these reliefs sticks you will bend a rod. Ask me how I know.

I have had the entire valve body out and restacked valves to operate like excavator controls.

The System is a very basic hyd system easy to rebuild easy to trouble shoot.

The sag is from oil moving back past the seals in the valve body. Depending on the tolerances in the valves some might be tighter than others. I doubt very much it is oil moving past seals in cylinders but it could be. However you would notice a drop in breakout with out laboring the tractor pump.

JD does have a spec on drop. The exact quote is in the archives somewhere. The search system here is a PITA. I do not remember the exact numbers but was surprised at what JD considered within tolerance.

Yes I agree the sag and the settling in 15 minutes or so is a irritation. I have no problem with it. Yes I operate BIG CATS and OTHERS. But for my use at home my little BH beats the snot out of a shovel and wheelbarrow. New o ring and seal kits are available.

I use the lite oil. Probably should use heavy. ....

Reply to |

Share This