Jinma 354 engine diagram oil leak

| locksleyred

Join Date: Mar 2006 Posts: 36 Victoria Australia

|

2014-02-01 188810

Hi people,

I have an oil leak on a 354 Jinma 4wd. It is coming from the rear of the engine but in front of the bell housing. So there is a 1mm clearence between the sump pan and the bell housing. The oil appears to be coming down from here. It drips every 2-3 seconds so quite large.

I have tightened the sump screws which were good except for the 4 at the rear ... !!!! .... but the leak kept going. I also undid the oil drain plug on the bell housing but no oil dripped. The oil is black so not gear box oil. I have done nothing yet but waiting on advice as to what to do and where to start first.

I have no blow up diagrams of the engine and bell housing as I suspect this is where I will have to split the tractor. It might be the sump gasket or worse ???...

anyway look forward to any replies.

I live in Australia.

Cheers

Mike

Reply to |

Jinma 354 engine diagram oil leak

| greg_g

Join Date: Jan 2004 Posts: 1816 Western Kentucky

|

2014-02-01 188811

That has been a common problem with the smaller engine in the 254, but this is the first time I've heard about it on a 354. The fix is inexpensive, but labor-intensive. You have to split the tractor between at the ball housing, to expose the clutchpack and flywheel. Both must then be removed to expose the loose bolt(s) that are causing the leak.

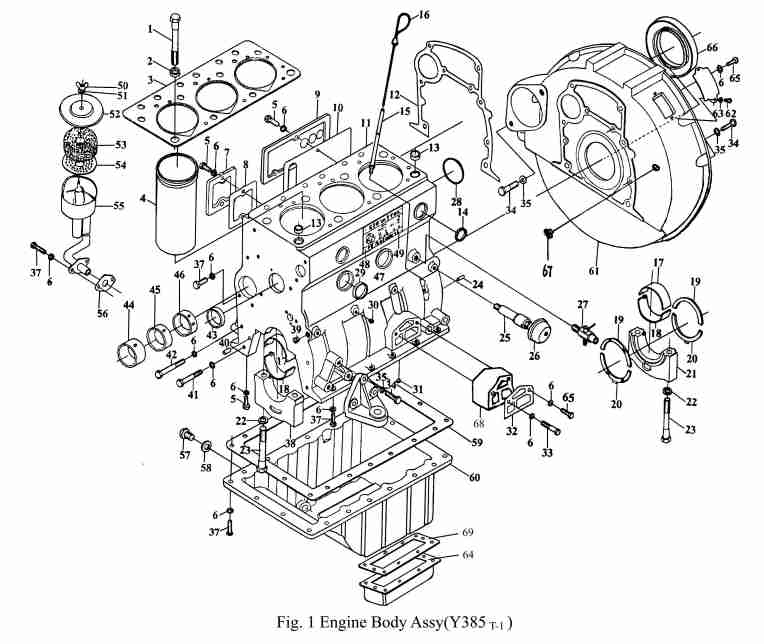

The shade tree route is to simply tighten down all the exposed bolts and hope for the best. The professional route would be to remove them all, after which you can remove the flywheel housing. That will expose the flywheel housing gasket (#12 in the diagram). Replace it, then put everything back together.

I didn't have a link to the 354 engine diagram, but the flywheel housing gasket is in the same place on both engines.

//greg// ....

Picture Link

Reply to |

Jinma 354 engine diagram oil leak

| richwaugh

Join Date: Mar 2010 Posts: 96

|

2014-02-01 188815

What Greg says is the most likely cause of your leak and you definitely want to address the issue sooner, rather than later. Waiting to fix runs the risk of the tractor being damaged by the loose joint between the flywheel housing and the engine.

I had the same issue with my 304 Jinma and detailed the whole thing here: http://chinesetractor.proboards.com/thread/689/major-tractor-woes-paradise?page=1

You'll want to examine and possibly replace your throwout bearing, pilot bushing and all the roll pins holding the clutch linkage while you're in there. Use doubled roll pins nested inside each other or the better spring-wound pins to insure against future failure. As long as you have to split the tractor you might as well take this opportunity to make everything in there as sound as possible. ....

Reply to |

Jinma 354 engine diagram oil leak

| locksleyred

Join Date: Mar 2006 Posts: 36 Victoria Australia

|

2014-02-02 188816

Thanks guys for your ideas. I know Greg has helped me before a few years back. And I have been reading your thread Rich informative and a laugh.

So gentlemen I guess it's not the sump seal? I was hoping it was but something inside told me it would be a little more than that.

Ok Ill have a go at splitting the tractor. One thing though is that spares here are not that easy to get and if you get them from China they more often than not send yu the wrong one.

Where do I find the blow up diagrams with the part details so I can use this to get parts, thanks Greg by the way for the engine one, that will be correct?

I'll clear a space in the garage, so how much gap do I need within the split to work easily on the job?

By the way Rich how many hours was the task in splitting and back together again?

I'll try and get a dolly made.... ah no maybe I better get one made ...lol

Won't be able to start for at least a week as we are having a few few hot days this summer. Been over 42o C the last few days and likely to be that for a week. Went to the beach today and it was 29oC had a good time came home and wish we didn't. 10 days ago had temps of 45.5oC for a few days, last week had to sleep with blankets on....go figure.

One thing more .... not getting the " don't lose the balls" where are they and why could I lose them?

Cheers

Guys and have a good one.

Mike ....

Reply to |

Jinma 354 engine diagram oil leak

| greg_g

Join Date: Jan 2004 Posts: 1816 Western Kentucky

|

2014-02-02 188817

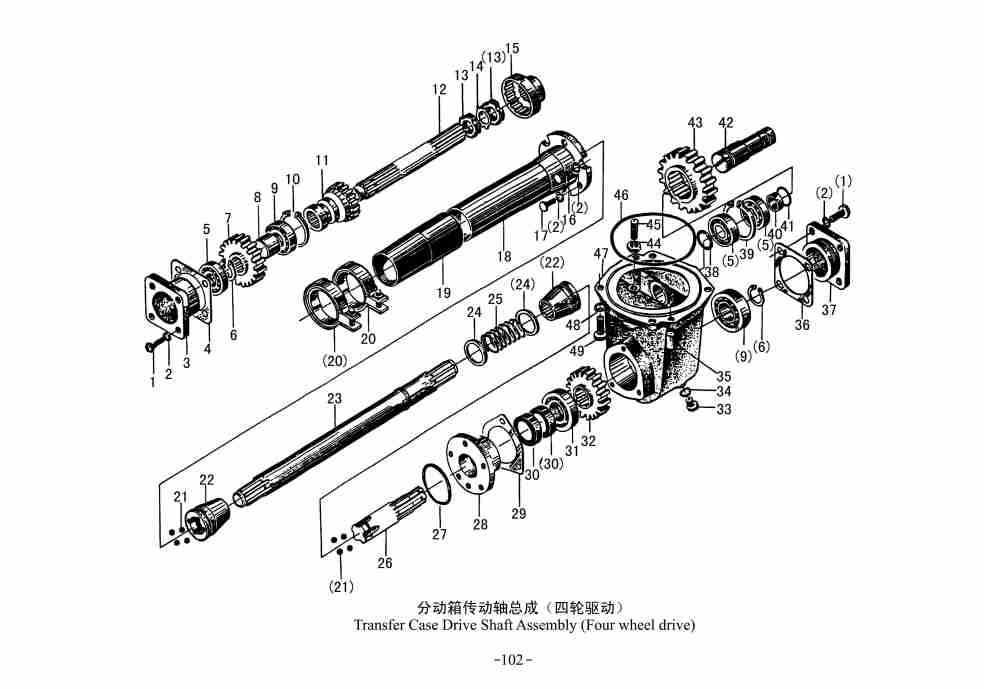

The front driveshaft is held in place by a handful of steel balls (#21 in the diagram). Note they're located at both the front and the rear of the shaft. These balls are held in place by a compression spring (#25). A lot of first timers are surprised by flying steel balls, and frustrated when they recover fewer than actually fell out.

The diagrams come from www.johnstractor.homestead.com, but they're no substitute for the actual operator/maintenance and parts manuals. I strongly suggest you order a set.

//greg// ....

Picture Link

Reply to |

Jinma 354 engine diagram oil leak

| locksleyred

Join Date: Mar 2006 Posts: 36 Victoria Australia

|

2014-02-04 188824

Hi All,

Split the tractor today, 4 hours for the bits and pieces and 10 mins to split, I bet it wont be 10 mins to put back together...lol.

No oil in the bell housing, dry as a bone. I will need a new clutch plate so this won't be a wasted exercise. The nuts holding the bell housing to the engine block were not loose at all 2 had just a 1/16 of a turn to go and I doubt that this could be the cause of the leak.

Have not taken the housing off yet, just ran out of daylight. I'll do it tomorrow.

Thrust bearing.... hmm I don't know, might take it to the bearing dealer in town and see what he says, there is a little play.

So thrust bearing, clutch plate what else should I look at getting? Checking?

The clutch bolts were gold 8.8 type what this means I don't know. Fly wheel bolts are just black, can't see any marks.

So 8 bolts tomorrow, black no markings, and away we go.

Can't get gaskets here so will have to make my own. Any suggestions?

Found all the balls Greg .. lol.

Ok evening all,

Cheers

Mike ....

Reply to |

Jinma 354 engine diagram oil leak

| greg_g

Join Date: Jan 2004 Posts: 1816 Western Kentucky

|

2014-02-04 188825

It's a dual stage clutch, so there are two friction plates to change; one for the drive line, one for the PTO. The PTO friction plate is between the clutchpack and the flywheel face. The other is internal to the clutchpack itself.

The two bearings to change are the pilot bearing (engine end of the nested driveshafts) and the throwout bearing (on the bearing carrier in the bell housing).

No marks on the hex head suggest grade 1 or 2 bolt. They don't take a lot of torque, so I'd expect lock washers. But conventional wisdom says to upgrade those bolts so you don't have to do this again. Most folks who've done this job trash those OE bolts and replace them with 8.8

8.8 on the hex head represents the bolt hardness. It's the metric equivalent to a grade 5 bolt.

You'll want to replace that gasket between the housing and the engine block too. You can either wait for a cheap Chinese cork gasket to come from a Jinma dealer, or cut your own from a bulk roll of oil&gas gasket material from an auto parts store. I recommend the latter.

//greg// ....

Reply to |

Jinma 354 engine diagram oil leak

| locksleyred

Join Date: Mar 2006 Posts: 36 Victoria Australia

|

2014-02-05 188830

Hello again,

Thanks for your comments and advice Greg,

Took the bell housing off and it was basically a mirror image of the photo that Rich had on his thread, see above for link, so we know where the problem is.

Waiting on a thrust bearing to come tomorrow but managed to buy all the seals and bearings needed to do the job. About $200 in total.

No way of getting a gasket here went to buy some paper but was advised by the guy in the shop to use . loctite Blue Maxx as the gasket sealant. Temp range of -60oC( not likely to ever happen here) to +250oC. Can't find what the temp at this part of the engine / gearbox is ever likely to reach.... any comments?

Made the alignment tool today so that's ready.

Thought I would need a new clutch plate(s) so took them to the clutch and brake shop but was told by the manager that if he was doing the job he would put them straight back in, so that's a saving.

Hmmm so now waiting for the bearing and I will do the cleaning and replacement as much as I can tomorrow.

OH... The local garage man said that the bolts look good quality and he would put them back in.

He said he would use 50 foot lbs for the course thread (very shiny black bolts) and 60flbs for the fine thread( 8.8 gold ones)bolts.

Any comments here? ........

Ok time to chill out and early night gonna be hot again tomorrow so early start before the heat.

Cheers

Mike ....

Reply to |

Jinma 354 engine diagram oil leak

| greg_g

Join Date: Jan 2004 Posts: 1816 Western Kentucky

|

2014-02-05 188842

I'll bet the counterman never split a tractor. Do NOT use gasket inna tube. He's just trying to sell you something cuz he doesn't have what you want. Go to another store to get the bulk gasket material. It's standard store stock in every NAPA store I've ever been in. And I think there is almost certainly some Australian equivalent.

And don't believe the man that said the black bolts are reusable either. The reason they came loose is that they're too soft. It's a known engineering fault with Jinmas, the problem started on the drawing board, it's simply a substandard engineering spec. In every case, the threads stretched. Put these bolts back in, and brace yourself for the same thing to happen all over again. Get harder bolts, GR5 or metric 8.8 will stop this problem in its tracks.

//greg// ....

Reply to |

Jinma 354 engine diagram oil leak

| locksleyred

Join Date: Mar 2006 Posts: 36 Victoria Australia

|

2014-02-06 188845

Hi All,

Went to Shepparton today, google it, big country city in Australias fruit and veg bowl. So you'd think I get plenty of help here.....nup. Unless what I have has a number, and chinese numbers are usless, you don't get a look in. Went to change bolts as suggested, and keep in mind they were never ever loose and I'll tell you why the gasket failed later, not one tractor place had any or could they suggest where I could get them except go to China.

Hmmm no luck there. My guess is that there was something available but because there was no number no one would look. Most of the sales people are still on mothers milk and long gone are the days when you went to Bill's and he said hmmm that looks like a such and such I know just the thing that will replace it.

This is a product of not having any manufacturing here in Oz.

OK Greg you say get paper and make one. Went to no less tha 10 businesses today actually showed them the bell housing and said this needs a gasket so I can attach to the block.

Guess what? Each came out and handed me a tube of gasket in a tube and said this is the thing now we use it all the time. Oh by the way this stuff is made in the USA.

Hm no luck there either. Got the thrust bearing pressed on and fly wheel bearing and seal so will do this I guess over the weekend.

While on my travels I asked various businesses what should the torque be on the bolts for

Bell Housing,

Fly Wheel,

Clutch mechinism

I got a complete range from 20flbs to 110 flbs!!!!!!

So anyone out there who knows what they should be???

Please let me know and thanks in advance.

I'm just havin no luck in finding out.

Oh one other question.... I forgot which way the PTO clutch plate should be against the flywheel :(

The plate has a long neck one side compared to the other my guess is that the short neck faces the flywheel.... am I right? It's a 2 stage clutch.

So why do I think the gasket failed. Well when I took off the damaged gasket I could not help noticing it was raised near where the leak was. I took it off only to find that the sump gasket was proud of the block by some 1.2mm and My guess is that the bell housing to block gasket had never taken up properly. It became a week spot which finally gave way. ie the gasket never fully compressed.

OK will keep you informed and any suggestions on torque would be very welcome, have a good one,

Cheers Mike

....

Reply to |

Jinma 354 engine diagram oil leak

| greg_g

Join Date: Jan 2004 Posts: 1816 Western Kentucky

|

2014-02-06 188850

Maybe bulk gasket material is called something different in Australian auto parts stores. There's an eBay.au link below. I'm still STRONGLY recommend you avoid the gasket inna tube solution. I don't care WHERE it comes from.

The flywheel housing bolts may not look or feel loose to the touch, the reason they leak is that the bolt threads stretch. Given no hardness markings on the hex head, you can bet they're pretty soft. I still recommend replacing them with new, preferably a metric 8.8 hardness.

I've now come to realize that you don't have the manuals for this tractor. I suggest you put them on the top of your shopping list. Answers like clutch adjustments, torque values, friction disc direction are all in there. Jinma manuals typically comprise a set of four; operation/maintenance of the tractor, parts for the tractor, operation/maintenance for the engine, parts for the engine.

There are two general rules for amount of torque; (depending upon whether or not a lock washer is involved. With an OE lock washer, you don't need a torque wrench. Simply tightened until the lock washer is fully compressed. Without lock washer, it's a function of hardness/diameter/thread count. Put "bolt torque chart" in your search engine, then take your pick. The values are pretty much universal.

You've yet to mention the pilot bearing. That's the small one that goes into the center hole of the flywheel. It supports the nested shafts that stick out of the bell housing. That should be replaced. As for the direction of the PTO clutch, it should be installed in the direction that leaves no gap between the splined center and the pilot bearing face. A depth gauge will help you with that decision.

Whether or not the actual cause of the leak was a misplaced sump gasket is not relative to the stretched threads on the flywheel housing bolts. You've removed the under-engineered bolts from the block, and they can't be "unstretched". Replace them.

//greg//

....

Link: bulk gasket material

Reply to |

Jinma 354 engine diagram oil leak

| locksleyred

Join Date: Mar 2006 Posts: 36 Victoria Australia

|

2014-02-10 188921

HI All.

Got the tractor back together today with the help of a friend who just happened by.. AND.. who had done this before.

BAsically went back in about 30 mins with just a bit of luck I guess. But have everything lined up and push gently and it all goes together.

Started putting the bits and pieces back but again ran out of light so will finish tomorrow.

Have read a lot of forumns on Jinmas and boy do they seem to have trouble if it's not this problem it's that. No wonder some people just give up and sell them on.

But I must say for what I do it's the perfect thing but then again I'm not rough with equipment either. I've had 2-3 problems which I fixed but they did cause me concern at the time.

Lost 1st and reverse gear as selector fork broke.

Could not get out of 4WD as selector lever,inside tractor, was too soft and just bent.

And had trouble with no lift in the bucket as small plactic bit in oil filter housing broke.

All of the above just poor quality bits and pieces.

Anyway will let you know if it starts today.

Cheers

Mike ....

Reply to |

Jinma 354 engine diagram oil leak

| locksleyred

Join Date: Mar 2006 Posts: 36 Victoria Australia

|

2014-02-13 188936

Hi All,

For some reason a post did not post. But in brief... thanks Greg and Rich for your help. Greg again in brief I tried everywhere to get the bulk gasket stuff. Finally I found some and the man said what are you using it for? I showed and told him he said nah we dont use that anymore we use this made in US and is s**t hot. So what does one do??????

Bolts well I just gave up went to two tractor repair places I said "You're fixing this tractor it's in your shop, you took out these bolts ....what would you do. ?" Both examined the bolts one used a scope and both said they are good bolts and they would put them straight back in at 65 ft lbs. So again what does one do???

ANyway all back together again and using it.

You guessed it ...have another problem.

Because I'm by myself I didn't notice oil being thrown out the back around the 3 point linkage area. I never touched this area at all.

I did replace the lifting hydraulics with hydraulic oil and noticed that when I looked inside the oil fill oil the oil was somewhat frothy ...?? but I couldn't see where it was coming from. I did also replace the oil filter connection as the old one just let the oil go straight through as the nylon seat inside had broken.

Did I use the wrong oil???? OR...??/?

I used the same hydraulic oil as I use for my log splitter ram.

I put the same oil in the power steering tank as well....is that wrong?

Cheers

Mike ....

Reply to |

Jinma 354 engine diagram oil leak

| greg_g

Join Date: Jan 2004 Posts: 1816 Western Kentucky

|

2014-02-13 188937

Assuming you use ISO32 hydraulic fluid, the frothing issue is likely an air leak. You've still got a loose fitting somewhere on the low pressure side (suction/return). It's almost certainly froth pushing out via the fill/vent that you're seeing in the rear. Check a cold dipstick too, just to make sure you didn't overfill.

//greg// ....

Reply to |

Jinma 354 engine diagram oil leak

| locksleyred

Join Date: Mar 2006 Posts: 36 Victoria Australia

|

2014-02-14 188948

Hi All,

Using ISO 46 hydraulic oil. No oil in the tank now but still can't see where it came out of.

When checking oil where a screw cap is involved, and on the Jinma a good length thread is used, do you unwind and then take the oil measurement ( like I do ) or do you just unscrew the cap and read the level? Always wondered about this.

I could see no air vent around the back. So it looks like I will have to refil and maybe get someone round the back to see where it's leaking from.

But from the spray over the tractor it kinda looks like it came out under pressure but again from where and if it did so, I wonder if I have damaged some seals. :(?

Cheers

Mike ....

Reply to |

Jinma 354 engine diagram oil leak

| greg_g

Join Date: Jan 2004 Posts: 1816 Western Kentucky

|

2014-02-14 188949

On (threaded) Asian dipsticks, common practice is not to screw them back in the hole if just a level check is to be performed. Unscrew, remove, wipe, set back on the hole, remove, check level. Clean hydraulic fluid is difficult to see on a dipstick, I always set the wet stick on a dry cloth and view the level that transferred to the cloth.

May I ask why you chose ISO46? That's thicker than ISO32; about a 20W equivalent as opposed to the 10W equivalency of ISO32. In this country, it's use in Chinese tractors is limited to warm areas - or to people who never use their tractor in the winter. Come cold season, your hydraulics are gonna take longer to warm up than during warm seasons. ISO32 is thin enough to overcome the issue.

//greg// ....

Reply to |

Jinma 354 engine diagram oil leak

| locksleyred

Join Date: Mar 2006 Posts: 36 Victoria Australia

|

2014-02-14 188950

Hi All,

Thanks Greg pretty much what I do but I will take your hint on the cloth and yes it works well.

The ISO 46 oil is what I had already and used it in my log splitter ram which I use late Autumn and Winter.

Here Winter aveage is about 15oC. Summer, well it's been 30oC - 40oC+ over the past 10 weeks with the occasional cold snap of 20oC.

Today I will see if I can locate the leak. I noticed that the oil filter wasn't screwed on tightly but no oil leak there. Still wondering where it's coming out from though.

Cheers

Mike ....

Reply to |

Jinma 354 engine diagram oil leak

| locksleyred

Join Date: Mar 2006 Posts: 36 Victoria Australia

|

2014-02-16 188961

HI All,

Apart from screwing home the oil filter which was a little loose, I checked all the connections which I took apart when I split the tractor and all seemed ok. I checked the others as well and all were tight.

I ran the tractor for about half an hour and nothing leaked out the back.

I did look inside the tank under the seat and noticed what I would call a little bit of frothing. I would imagine that in any closed circut system like this there would be a little frothing.

Am I right in assuming this?

Cheers

Mike ....

Reply to |

Jinma 354 engine diagram oil leak

| greg_g

Join Date: Jan 2004 Posts: 1816 Western Kentucky

|

2014-02-17 188966

No, it's actually an open system. Unless you have the wrong fill plug that is. There are supposed to be several vent holes drilled into the fill plug, which is why I think I called it a vent/fill plug before. There may be a tiny bit of frothing due to fluid sloshing around. Any more than that - especially if the fluid lever is correct - strongly suggests an air leak on the suction/return side. But if your level is correct, and there's no fluid running down the backside of the tractor, I wouldn't give it any further thought.

//greg// ....

Reply to |

Jinma 354 engine diagram oil leak

| locksleyred

Join Date: Mar 2006 Posts: 36 Victoria Australia

|

2014-02-17 188973

Thanks Greg. The tractor was in the shed and I worked the bucket for about 30 minutes up / down open / shut etc and the frothing made the level on the dip stick go up by 1/4 of an inch not more than that.

And I see the really small holes on the filler plug.

I'll give it a work out today moving some logs around, and I'll watch very carefully to see if any oil comes out.

I see you guys are having a bit of a cold time re the weather. We can't imaging what you are going through looking at the news footage. Here we are having the exact opposite and some parts of the state are receiving no rain at all and the fires here were out of control last week. Smoke so bad that you could not see the sun. No good if you have asthma. Wonder what winter will be like? Not like yours I hope.

Cheers

Mike ....

Reply to |

Jinma 354 engine diagram oil leak

| greg_g

Join Date: Jan 2004 Posts: 1816 Western Kentucky

|

2014-02-18 188983

Those really small holes actually "breathe" as the hydraulics work; in on ram extension, out on retraction. So dirt/chaff in the air is going to stick to the naturally oily holes. Eventually they plug up, which essentially turns a vented system into a closed system. I cleaned my vent/fill plug with a kerosene soak followed by a few directed blasts of compressed air, at least twice a year during spring and fall maintenance. If you work in particularly dry dusty conditions, it likely needs cleaning more often.

//greg// ....

Reply to |

Jinma 354 engine diagram oil leak

| locksleyred

Join Date: Mar 2006 Posts: 36 Victoria Australia

|

2014-02-18 188987

Well gave the tractor a workout today lifting and moving logs about. No sign of any leak at the back. So all is I hope well with the tractor.

Cheers

Mike ....

Reply to |

Jinma 354 engine diagram oil leak

| gears1

Join Date: Jun 2009 Posts: 0 London, Ontario

|

2023-12-25 201763

Picture of new Jinma 284 gasket showing measurements. ....

Picture Link

Reply to |

Jinma 354 engine diagram oil leak

| gears1

Join Date: Jun 2009 Posts: 0 London, Ontario

|

2023-12-25 201764

Measurements of gasket from Jinma 284. ....

Picture Link

Reply to |

Share This