Agricat 254 PTO clutch does not disengage

| RickCarr

Join Date: Jan 2014 Posts: 4 Arkansas

|

2014-02-05 188832

I have an Agricat 254 that has had a problem with the PTO ever since I bought it about 3 years ago. I normally just use it for the loader. I figure it's about time to fix the problem. The issue is that the PTO can't be disenguaged, if the tractor is running it is turning. Has anyone had any problem like this?

Thanks for the input

Rick

Reply to |

Agricat 254 PTO clutch does not disengage

| greg_g

Join Date: Jan 2004 Posts: 1816 Western Kentucky

|

2014-02-05 188843

Use some degreaser and inspect the PTO engage/disengage lever linkage carefully, with special consideration to where it goes horizontal to enter the housing. There's a little device there with balls that fit into holes. That's all that keeps the PTO either engaged or disengaged; a ball that rolls in and out of a hole. Very common for this mechanism to (a) get too dirty to move, and/or (b) lose a ball.

//greg// ....

Reply to |

Agricat 254 PTO clutch does not disengage

| RickCarr

Join Date: Jan 2014 Posts: 4 Arkansas

|

2014-02-10 188922

Thanks for the input Greg.

Unfortunantly I don't think its that simple.

The lever moves to the two positions and the ball is there and can be seen dropping into place at both ends of travel.

There is a red silicon on the covers in this area indicating that someone has been inside this part of the tractor before.

Any more ideas before I dive in?

Thanks

Rick ....

Reply to |

Agricat 254 PTO clutch does not disengage

| greg_g

Join Date: Jan 2004 Posts: 1816 Western Kentucky

|

2014-02-11 188924

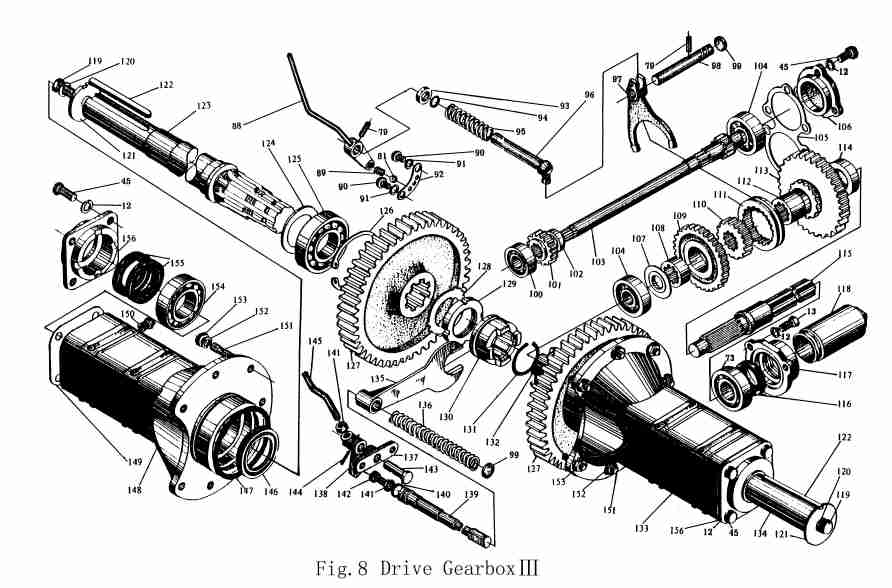

If it's working on the outside, then you have little choice but to "dive in". On the inside end of the horizontal shaft (96) is a piece that's often called the "shift lump". It's a cast finger that's been known to break off. The finger slots into a fork (97) which moves a sliding gear (111)that engages/disengages the PTO driven gear (112) depending upon the position of the PTO lever (88). Alternatively roll pin ((79) could have broken, which means that fork (97) could be out of place on rod (98)

To get to that, you have to remove the operator seat and the hydraulic sump. And when you go to putting it back together, you might want to consider cleaning off that gasket inna tube, and replacing it with a proper fixed gasket. You should be able to get one from/through any Jinma dealer.

//greg// ....

Picture Link

Reply to |

Share This